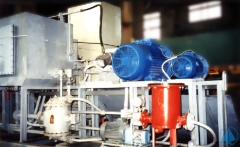

Test stand for pumps and hydraulic motors of road-building machines

The stand is used for testing

pumps and hydraulic motors of road-building machines after routine and capital

repair. The stand

checks pumps functioning per GOST 14658-86 and hydraulic motors functioning per GOST

20719-83 to the extent as

specified by the statement of work approved by the Customer.

The stand allows checking pumps and

hydraulic motors functioning (brand marks of equipment tested and test

conditions are given in the tables below).

Pumps are tested for:

- excessive

vibration, shock, knocking, sharp noise, line pressure surge, excessive heating

- drop formation along the covers, plugs, flanges, joints, etc.

- amount of working fluid supply and its consistency at the given direction of output shaft rotation

- change of working fluid supply amount during control mechanisms operation

- response to load change (output pressure)

Hydraulic motors are tested for:

- excessive vibration, shock, knocking, sharp noise, line pressure surge, excessive heating, conditions of working fluid outlet from the drain pipe (uniformity, air bubbles, etc.)

- working fluid leaks from plugs, flanges, shaft, etc.

- rotation of hydraulic motor output element during working fluid supply to working cavities

- change of rotation of hydraulic motor output element when changing working fluid supply to the working cavities

Pumps brand marks and test conditions:

|

Pump

|

Ðtest,

MPa

|

|

|

Ntest,

kW

|

|

333.355.100.220

|

20

|

168

|

1,500

|

56

|

|

NSh-100À-3L

|

16

|

135

|

1,500

|

36

|

|

NSh-71À-3L

|

20

|

105

|

1,500

|

35

|

|

NSh-50 U-2

|

16

|

73

|

1,500

|

20

|

|

NSh-50

|

14

|

73

|

1,500

|

17

|

|

74860276

|

6.5…7.3

|

86

|

1,500

|

10

|

|

2909124SL

|

1

|

45

|

1,500

|

0.75

|

|

NSh-10P-3

|

16

|

13

|

1,500

|

3.5

|

Hydraulic

motors brand marks and test conditions:

|

Hydraulic motors

|

Ðtest,

MPa

|

Qtest, l/min

|

ntest, rev/min

|

Ntest,

kW

|

|

310.3.56.00

|

20

|

2.8…100

|

50…1,800

|

30

|

|

310.2.56.00

|

20

|

2.8…100

|

50…1,800

|

30

|

|

310.3.112.00

|

20

|

5.6…201

|

50…1,800

|

60

|

|

303.3.112.501

|

20

|

5.6…201

|

50…1,800

|

60

|

|

303.3.112.501.002

|

20

|

5.6…201

|

50…1,800

|

60

|

|

MN-250

|

16

|

12.5…250

|

50…1,000

|

60

|

|

Stand

performance

|

No

less than 3 standard-size hydraulic units per 8 hours

|

|

Total

consumed power, kW

|

60.5

|

|

Ambient

temperature, ºÑ

|

10…25

|

|

Water

temperature at the heat exchanger inlet, ºÑ

|

0…30

|

|

Working

fluid viscosity, cSt

|

10…30

|

|

Reservoir

volume, m3

|

1.2

|

|

Stand

dimensions (WxLxH), mm

|

2,000x4,500x2,000

|

Apart

from the hydraulic units specified above, the stand can be used to test any

hydraulic units which fit stand capacities. Cheltec is able to design and manufacture any

necessary adapters.

Home

Home Contacts

Contacts Sitemap

Sitemap